Building tensile structures can be a complex process, but it offers a unique and visually striking design solution. Here are some steps involved in building a tensile structure for a building:

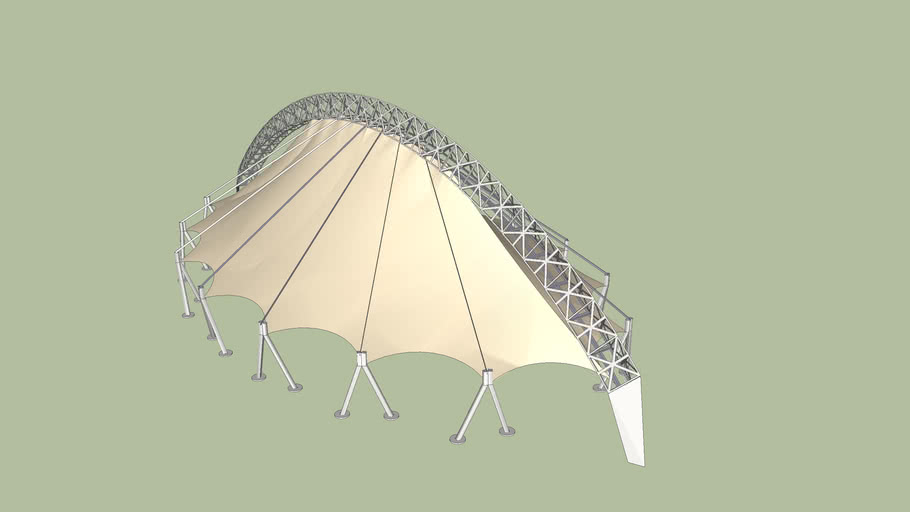

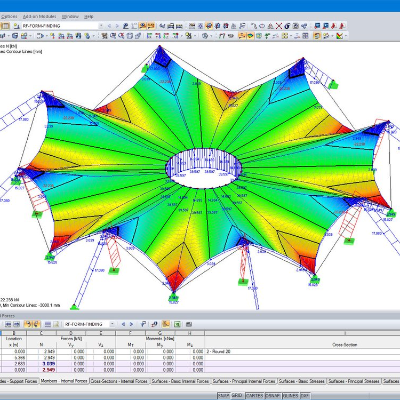

1. Design: The first step in building a tensile structure is to develop a design that meets the specific needs of the building. This involves working with architects, engineers, and fabricators to create a design that is both functional and aesthetically pleasing.

2. Fabrication: Once the design has been developed, the fabricator will create a detailed shop drawing that includes all the necessary dimensions, materials, and fabrication details. The fabricator will then create the fabric panels and steel or aluminum frame components based on the shop drawing.

3. Installation: The installation process involves erecting the steel or aluminum frame, attaching the fabric panels to the frame, and tensioning the fabric to create the desired shape. The installation process may require cranes, scaffolding, or other specialized equipment to ensure the structure is installed safely and securely.

4. Maintenance: Once the tensile structure is installed, it requires regular maintenance to ensure it continues to function properly and looks its best. This may include cleaning the fabric panels, inspecting the frame for damage or wear, and making any necessary repairs.

Overall, building a tensile structure for a building requires careful planning, design, fabrication, and installation. However, the end result is a unique and visually striking structure that can enhance the aesthetic of the building and provide functional benefits such as shade and energy efficiency.

A building tensile structure is a unique and visually appealing option for creating a modern and functional building. Tensile structures are lightweight, flexible, and can be customized to fit the specific needs of the building. Here are some examples of how tensile fabric can be used for building structures:

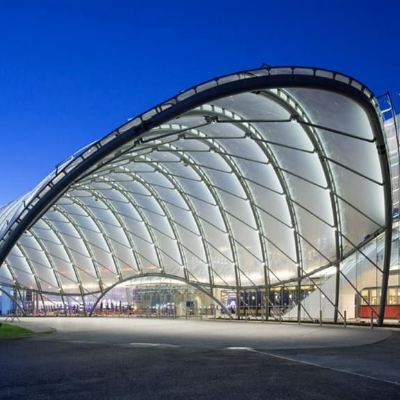

1. Tensile roof: Tensile fabric can be used to create a tensile roof for buildings. The fabric can be stretched over a frame to create a lightweight and flexible roof that provides shade and protection from the elements. It can also be used to improve energy efficiency by reducing solar heat gain.

2. Tensile facades: Tensile fabric can be used to create a unique facade for a building. The fabric can be stretched over a frame to create a three-dimensional shape that is both functional and visually appealing. It can also be used to provide shade and improve energy efficiency by reducing solar heat gain.

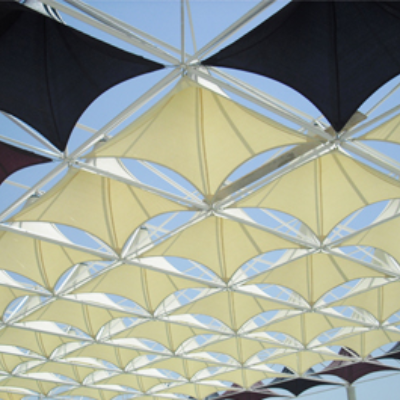

3. Tensile atrium: Tensile fabric can be used to create an atrium in a building that provides natural light and ventilation. The fabric can be used to create a lightweight and flexible roof that allows maximum sunlight to enter the space. It can also be used to create a unique and visually appealing design that complements the surrounding architecture.

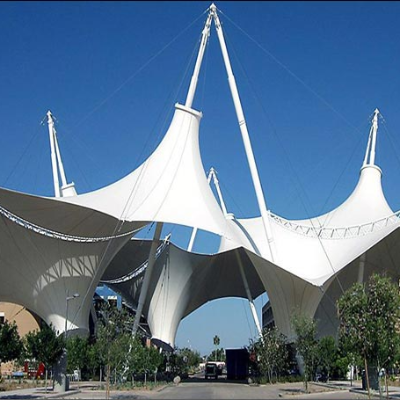

4. Tensile canopies: Tensile fabric can be used to create canopies over building entrances, walkways, and outdoor seating areas. The fabric can be stretched over a frame to create a lightweight and flexible structure that provides shade and protection from the elements.

5. Interior spaces: Tensile fabric can be used to create unique and visually appealing interior spaces. The fabric can be used to create a lightweight and flexible ceiling or wall panel that adds visual interest to the space.

Overall, a building’s tensile structure offers a unique and visually appealing option for creating a modern and functional building. Tensile structures can be customized to fit the specific needs of the building and can be designed to complement the surrounding architecture and landscape.

Tensile fabric buildings are known for their unique shape and design. They are made by stretching a fabric membrane over a structural framework. Here are some popular shapes and designs for tensile fabric buildings:

1. Cone-shaped: A cone-shaped tensile fabric building is a popular choice for outdoor event spaces like amphitheaters, outdoor stages, and pavilions.

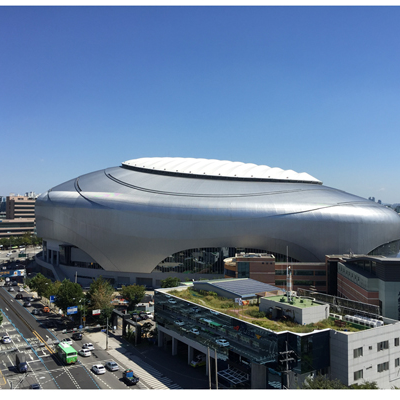

2. Spherical: A spherical tensile fabric building is a globe-shaped structure that can be used for a variety of purposes like indoor sports arenas, exhibition spaces, and entertainment venues.

3. Hyperbolic paraboloid: A hyperbolic paraboloid tensile fabric building is a structure that is characterized by its saddle-like shape. It is a popular choice for large-scale commercial buildings, like airports, convention centers, and shopping malls.

4. Pyramid: A pyramid-shaped tensile fabric building is a popular choice for outdoor pavilions, playgrounds, and park structures.

5. Sail-shaped: A sail-shaped tensile fabric building is a structure that is inspired by the shape of a sail. It is a popular choice for outdoor event spaces like weddings, receptions, and parties.

6. Wing-shaped: A wing-shaped tensile fabric building is a structure that is inspired by the shape of a bird's wing. It is a popular choice for large-scale commercial buildings like airports, convention centers, and museums.

7. Barrel-vaulted: A barrel-vaulted tensile fabric building is a structure that is characterized by its arched shape. It is a popular choice for large-scale commercial buildings like airports, convention centers, and museums.

There are several benefits of using a tensile fabric membrane for a building structure:

1. Lightweight and Flexible: Tensile fabric membranes are lightweight and flexible, making them ideal for creating unique shapes and designs that are not possible with traditional building materials.

2. Cost-Effective: Compared to traditional building materials like concrete and steel, tensile fabric membranes are more cost-effective. They require less material and labor to install, which can save you money in the long run.

3. Energy-Efficient: Tensile fabric membranes are translucent and allow natural light to enter the building, reducing the need for artificial lighting. They can also be coated with a reflective material that helps to reduce heat gain, making them more energy-efficient.

4. Durability: Tensile fabric membranes are designed to withstand harsh weather conditions like wind, rain, and snow. They are also resistant to fire, mildew, and UV rays, making them a durable and long-lasting option for building structures.

5. Quick Installation: Tensile fabric membranes can be installed quickly and easily, which can speed up the construction process and reduce project timelines.

6. Customizable: Tensile fabric membranes can be customized to fit any shape or size, making them a versatile option for building structures. They can also be printed with graphics or branding, making them a great option for advertising or marketing purposes.

7. Sustainable: Tensile fabric membranes are a sustainable building material that can be recycled at the end of their life cycle. They are also made from materials that have a low carbon footprint, making them an eco-friendly option for building structures.

Walkway Structure

Walkway Structure Tensile Umbrella

Tensile Umbrella Tensile Gazebo

Tensile Gazebo Awning Shade

Awning Shade Tensile Structure

Tensile Structure Swimming Pool Enclosures

Swimming Pool Enclosures Tensile Roof Shade

Tensile Roof Shade Shade Sail

Shade Sail Architectural Umbrellas

Architectural Umbrellas Auditorium Tensile Structure

Auditorium Tensile Structure Tensile Car Parking

Tensile Car Parking Conical Tensile Structure

Conical Tensile Structure Modular Tensile Structure

Modular Tensile Structure Outdoor Tensile Structures

Outdoor Tensile Structures Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Retractable Roof

Retractable Roof Tensile Architecture

Tensile Architecture Tensile Membrane Structure

Tensile Membrane Structure Tensile Roof

Tensile Roof Fabric Roof

Fabric Roof Hyper Tensile Structure

Hyper Tensile Structure Playground Canopies

Playground Canopies Tensile Canopy

Tensile Canopy Tensile Fabric Structure

Tensile Fabric Structure Tensile Facade

Tensile Facade Tensile Pergola

Tensile Pergola Tension Fabric Structure

Tension Fabric Structure Badminton Court Tensile Structure

Badminton Court Tensile Structure Restaurants Tensile Structure

Restaurants Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Amphitheater Tensile Structure

Amphitheater Tensile Structure Airport Tensile Structure

Airport Tensile Structure Tensile Shelter

Tensile Shelter Lawn Tensile Structure

Lawn Tensile Structure Garden Tensile Structure

Garden Tensile Structure Marriage Hall Tensile Structure

Marriage Hall Tensile Structure Terrace Tensile Structure

Terrace Tensile Structure House Tensile Structure

House Tensile Structure Roofing Tensile Structure

Roofing Tensile Structure Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Entrance Canopy

Tensile Structure for Entrance Canopy Tensile Structure for Public Spaces

Tensile Structure for Public Spaces Tensile Structure for Banquet

Tensile Structure for Banquet Anticlastic Structure

Anticlastic Structure Synclastic Structure

Synclastic Structure Linear Tensile Structures

Linear Tensile Structures Three Dimensional Tensile Structures

Three Dimensional Tensile Structures Surface Stressed Tensile Structures

Surface Stressed Tensile Structures Cable Net Membrane Structure

Cable Net Membrane Structure Hyperbolic Paraboloid Tensile Structure

Hyperbolic Paraboloid Tensile Structure Petrol Pump Tensile Canopy

Petrol Pump Tensile Canopy Toll Plaza Tensile Canopy

Toll Plaza Tensile Canopy Arch Supported Tensile Structure

Arch Supported Tensile Structure Barrel Roof Walkways

Barrel Roof Walkways Canopy Membrane

Canopy Membrane Atrium Tensile Architecture

Atrium Tensile Architecture School Tensile Structure

School Tensile Structure Tensile Landscape Structure

Tensile Landscape Structure Shell Structure

Shell Structure Tensile Pavilion Architecture

Tensile Pavilion Architecture Interior Tensile

Interior Tensile Tensile Dome

Tensile Dome Indoor Tensile Structure

Indoor Tensile Structure Tennis Court Tensile Roof Fabric Structure

Tennis Court Tensile Roof Fabric Structure Tensile Fabric False Ceiling and Stretch Ceiling

Tensile Fabric False Ceiling and Stretch Ceiling Tensile Structure Food Court

Tensile Structure Food Court Tensile Stretch Ceiling

Tensile Stretch Ceiling Serge Ferrari Fabric

Serge Ferrari Fabric Mehler Tensile Fabric

Mehler Tensile Fabric Acoustic Blinds

Acoustic Blinds Roller Blinds

Roller Blinds Mast Supported Tensile Structure

Mast Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Parallel Tensile Structure

Parallel Tensile Structure