Architractile is popular tensile fabric structure and canopy manufacturers in India. Architractile is best known tensile fabric architecture in India last few decades. Tensile fabric canopy is most demanding structure in Indian continent. Tensile fabric India is used in various application like as a roof, canopy, shading, building, texture, ceiling, covering, facade, shelters and textures. We are offering best tensile fabric roof cost in India. We have best structure designs of tensile fabric structures in architecture. We have best design and quality tensile fabric material used in manufacturing of tension fabric canopy in India.

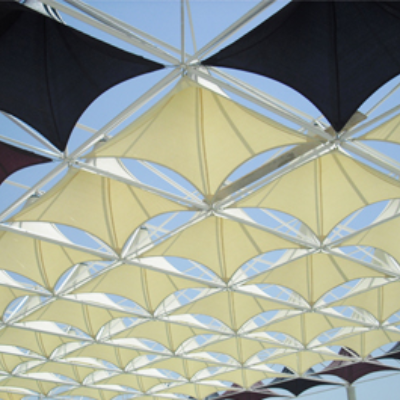

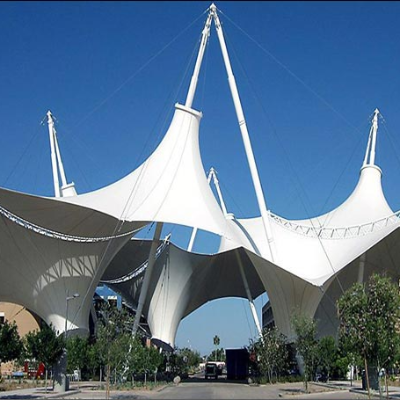

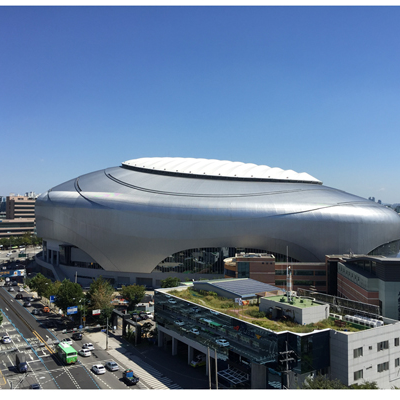

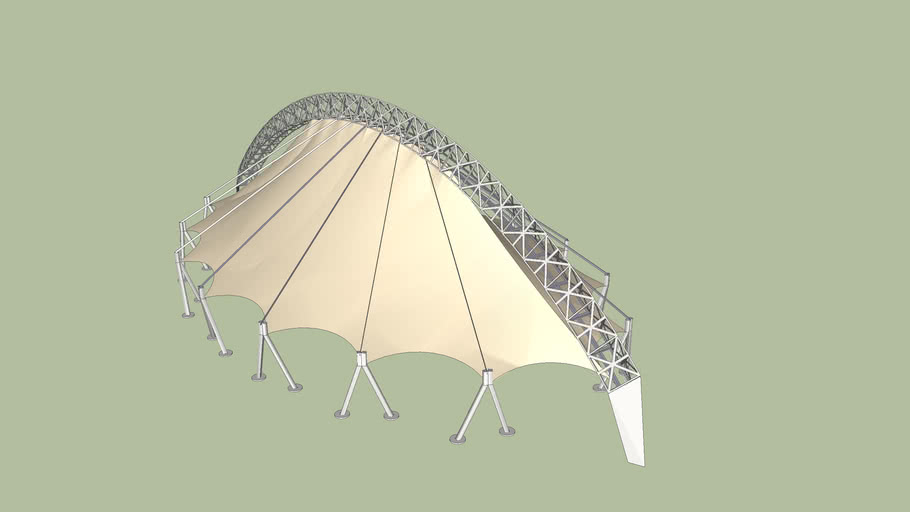

Fabric structures are tensile structures that "stretch" a membrane to a three-dimensional surface that can be used to build a canopy, ceiling, covering, façade, shade, shelters, textures, roof, shading, or decorative portion. Many tensile fabric structures described as 'modern tabernacles' are of low material content relative to other construction types and are usually transparent. Still, they provide little thermal weight of isolation.

The membrane usually consists of a woven base clothing coated on either side and retains stress forces exerted by a structural structure or cable system. Contrary to traditional roofing schemes, structures of fabric may cover vast areas without columns. This makes them perfect for buildings like sports faculties, auditoriums, shopping malls, transport exchange, etc. They can be constructed relatively quickly and relocatable to temporary purposes, which means that buildings such as circus tents or military uses are connected historically. We are the Manufacturer, Designer, Contractor, Dealer, vendor, Architect, design, engineering, manufacturing, and installation Company of fabric structures and tensile fabric structures.

The origins of the material systems can be dated from the ice age and Siberian Steppe for more than 44,000 years, where traces of primitive shelters built from animals wrapped between sticks have been discovered. Tensile fabric structure manufacturing systems have been built and flourished mainly in areas with limited material or survival, all exacerbated by low rainfalls—the tent developed through the years into an emblem of frivolity from these strictly utilitarian beginnings. Tensile fabric roof Manufacturing systems were almost exclusively recreational and were implemented in ways that were contradictory to their practical context, rather than for military purposes.

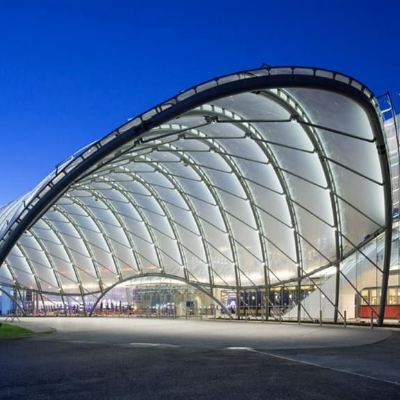

This had to improve in the 19th and 20th centuries when architects were influenced by scientific breakthroughs of architectural philosophy and structural engineering on a modern functional aesthetic. It led to remarkable designs synonymous with modern industrial systems as the Hajj Terminal roof at Airport Jeddah, Millennium Cathedral, and Denver International Airport. The architect Frei Otto started an intensive analysis of the design values behind a new generational structural building.

Material

The earliest fabrics were composed of direct, animal, or vegetable membranes. Subsequently, these membranes were cut into strips and twisted into more comprehensive, more functional textiles and gradually twisted into circular parts, which allowed the development of versatile, continuous, high-strength fibers. The first fiber to be structurally durable was cotton, but new fabric structures appear to be manufactured in polyester or PTFE coated glass. Topcoats of PVC-coated polymer lacquers (PVDF) improve their 'cleanability' and offer additional protection. This material will last 15-20 years or around five years in places where sunlight is heavily exposed in average climates.

PTFE coated glass fabric is costly but stable and long-lasting and can last between 30 and 50 years. It also benefits from low maintenance and self-cleaning. In recent years, high-performance materials such as silicones, PTFE fiber, ETFE film, laminated open grids, separated and phase changes materials remain industry norms for PVC coated polyester PTFE coated glass. These tensile fabrics are available in various thicknesses, weights, Colors, and translucencies (sometimes known as structural membranes or architectural fabrics). See the development of structural membranes and architectural fabrics for more detail.

Walkway Structure

Walkway Structure Tensile Umbrella

Tensile Umbrella Tensile Gazebo

Tensile Gazebo Awning Shade

Awning Shade Tensile Structure

Tensile Structure Swimming Pool Enclosures

Swimming Pool Enclosures Tensile Roof Shade

Tensile Roof Shade Shade Sail

Shade Sail Architectural Umbrellas

Architectural Umbrellas Auditorium Tensile Structure

Auditorium Tensile Structure Tensile Car Parking

Tensile Car Parking Conical Tensile Structure

Conical Tensile Structure Modular Tensile Structure

Modular Tensile Structure Outdoor Tensile Structures

Outdoor Tensile Structures Swimming Pool Tensile Structure

Swimming Pool Tensile Structure Retractable Roof

Retractable Roof Tensile Architecture

Tensile Architecture Tensile Membrane Structure

Tensile Membrane Structure Tensile Roof

Tensile Roof Fabric Roof

Fabric Roof Hyper Tensile Structure

Hyper Tensile Structure Playground Canopies

Playground Canopies Tensile Canopy

Tensile Canopy Tensile Facade

Tensile Facade Tensile Pergola

Tensile Pergola Tension Fabric Structure

Tension Fabric Structure Badminton Court Tensile Structure

Badminton Court Tensile Structure Restaurants Tensile Structure

Restaurants Tensile Structure Cantilever Tensile Structure

Cantilever Tensile Structure Inverted Umbrella Tensile Structure

Inverted Umbrella Tensile Structure Amphitheater Tensile Structure

Amphitheater Tensile Structure Airport Tensile Structure

Airport Tensile Structure Tensile Shelter

Tensile Shelter Lawn Tensile Structure

Lawn Tensile Structure Garden Tensile Structure

Garden Tensile Structure Marriage Hall Tensile Structure

Marriage Hall Tensile Structure Terrace Tensile Structure

Terrace Tensile Structure House Tensile Structure

House Tensile Structure Roofing Tensile Structure

Roofing Tensile Structure Tensile Structure for Building

Tensile Structure for Building Tensile Structure for Parking

Tensile Structure for Parking Tensile Structure for Entrance Canopy

Tensile Structure for Entrance Canopy Tensile Structure for Public Spaces

Tensile Structure for Public Spaces Tensile Structure for Banquet

Tensile Structure for Banquet Anticlastic Structure

Anticlastic Structure Synclastic Structure

Synclastic Structure Linear Tensile Structures

Linear Tensile Structures Three Dimensional Tensile Structures

Three Dimensional Tensile Structures Surface Stressed Tensile Structures

Surface Stressed Tensile Structures Cable Net Membrane Structure

Cable Net Membrane Structure Hyperbolic Paraboloid Tensile Structure

Hyperbolic Paraboloid Tensile Structure Petrol Pump Tensile Canopy

Petrol Pump Tensile Canopy Toll Plaza Tensile Canopy

Toll Plaza Tensile Canopy Arch Supported Tensile Structure

Arch Supported Tensile Structure Barrel Roof Walkways

Barrel Roof Walkways Canopy Membrane

Canopy Membrane Atrium Tensile Architecture

Atrium Tensile Architecture School Tensile Structure

School Tensile Structure Tensile Landscape Structure

Tensile Landscape Structure Shell Structure

Shell Structure Tensile Pavilion Architecture

Tensile Pavilion Architecture Interior Tensile

Interior Tensile Tensile Dome

Tensile Dome Indoor Tensile Structure

Indoor Tensile Structure Tennis Court Tensile Roof Fabric Structure

Tennis Court Tensile Roof Fabric Structure Tensile Fabric False Ceiling and Stretch Ceiling

Tensile Fabric False Ceiling and Stretch Ceiling Tensile Structure Food Court

Tensile Structure Food Court Tensile Stretch Ceiling

Tensile Stretch Ceiling Serge Ferrari Fabric

Serge Ferrari Fabric Mehler Tensile Fabric

Mehler Tensile Fabric Acoustic Blinds

Acoustic Blinds Roller Blinds

Roller Blinds Mast Supported Tensile Structure

Mast Supported Tensile Structure Barrel Vault Tensile Structure

Barrel Vault Tensile Structure Parallel Tensile Structure

Parallel Tensile Structure